SPUTTER technology SCIL®

The PLATIT coating unit Pi411 uses the patented SCIL® technology (SPUTTERED Coating Induced by Lateral Glow Discharge) to achieve high deposition rates with SPUTTERING. SCIL® allows for high-performance SPUTTERING from the central cathode.

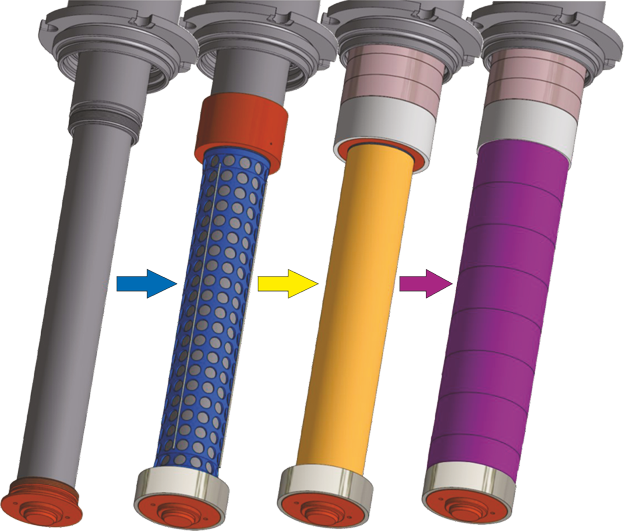

The cathode consists of:

- Cathode body, including magnetic coils with up to 30 kW of SPUTTERING power

- Perforated pipe for coolant inlet

- Membrane pipe tensed by internal cooling water for good conductivity to the target rings

- Metal or ceramic target rings

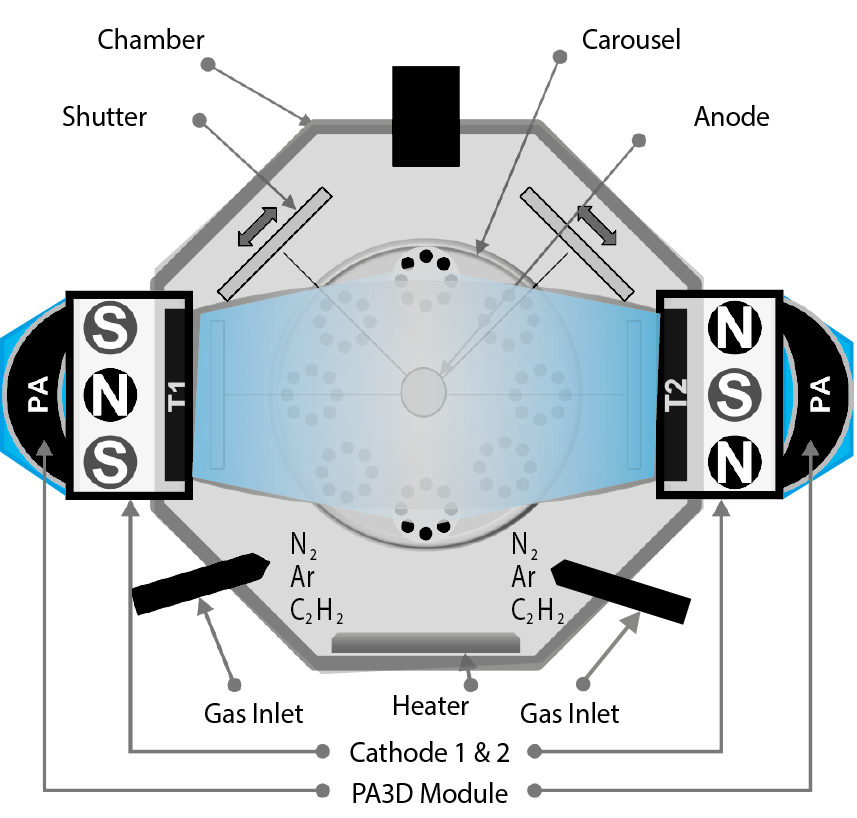

PA3D SPUTTER technology

The PLATIT 3D module (newly developed Helmholtz system) is used in the coating unit PL711 to offer the following advantages over conventional SPUTTER technology:

- High plasma density concentrated in the carousel

- No plasma deadlock zones

- No hollow cathodes

- Minimal cleaning effort after DLC processes necessary

- Higher deposition rates with uniform coating homogeneity

- Stable coating processes < 0.1 Pa

- Improved etching efficiency, stable etching processes < 0.2 Pa

- Variable magnetic field strength in the SPUTTER cathodes