Decoating with CT20

Equipment for decoating in an integrated coating process

Decoating is an important prerequisite for high-quality coating in PVD unit. The old, worn coating is thoroughly removed during this process so that the new PVD coating adheres well to the reground tool and achieves high performance. Regrinding without prior decoating leads to a continuous reduction in the service life of your tools.

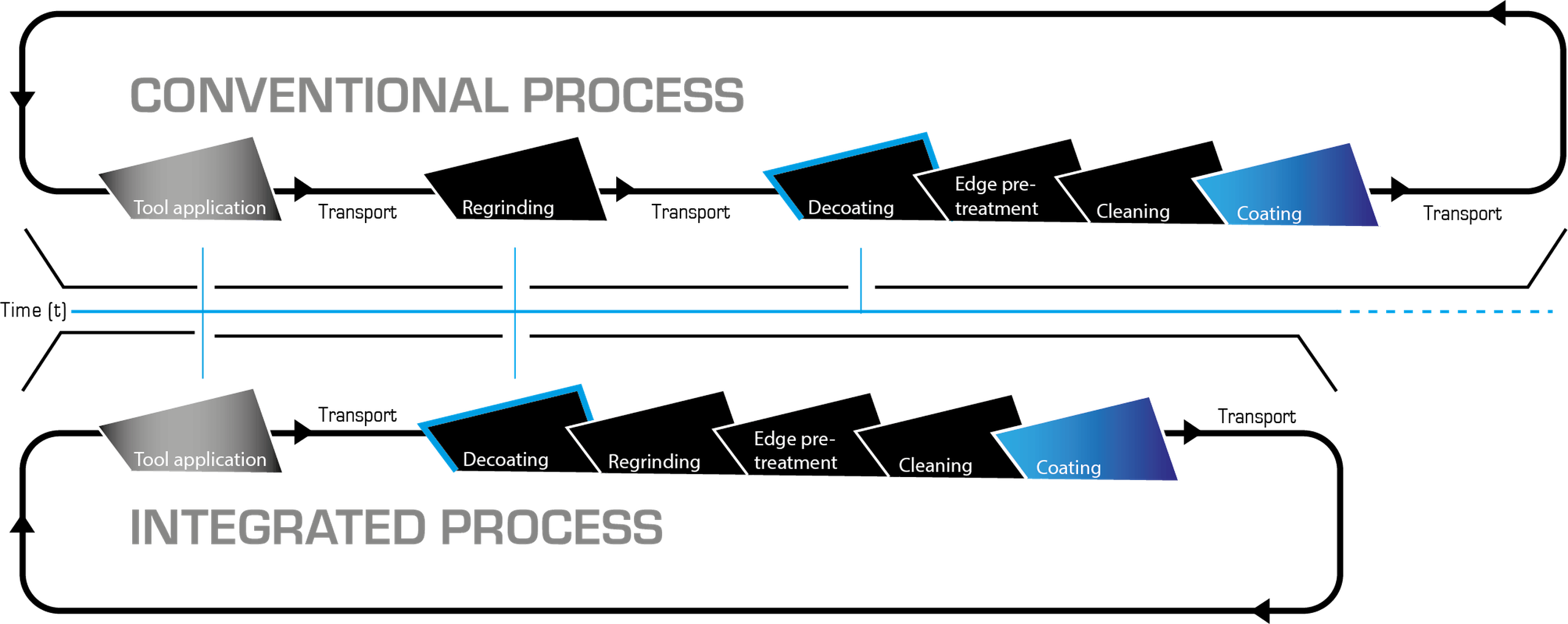

In conventional coating centers, tools are usually only decoated after regrinding

Decoating after regrinding can damage the final geometry of the tool and result in significantly poorer adhesion of the new PVD coating.

In addition, there is a risk of tool damage during packaging, transport, and repackaging.

In the integrated coating process, decoating takes place before regrinding

PLATIT is taking a more innovative approach here: By integrating decoating into your tool regrinding process, decoating can take place before regrinding. This immediately offers several advantages:

- It reduces the effort for transport and packaging within the coating process.

- Less damage is caused by handling.

- After regrinding, the tool is not chemically attacked.

- The edge pre-treatment can develop its full effect.

- It creates the conditions for optimum adhesion.

- It comes close to the performance of a new tool.

There are two types of decoating units

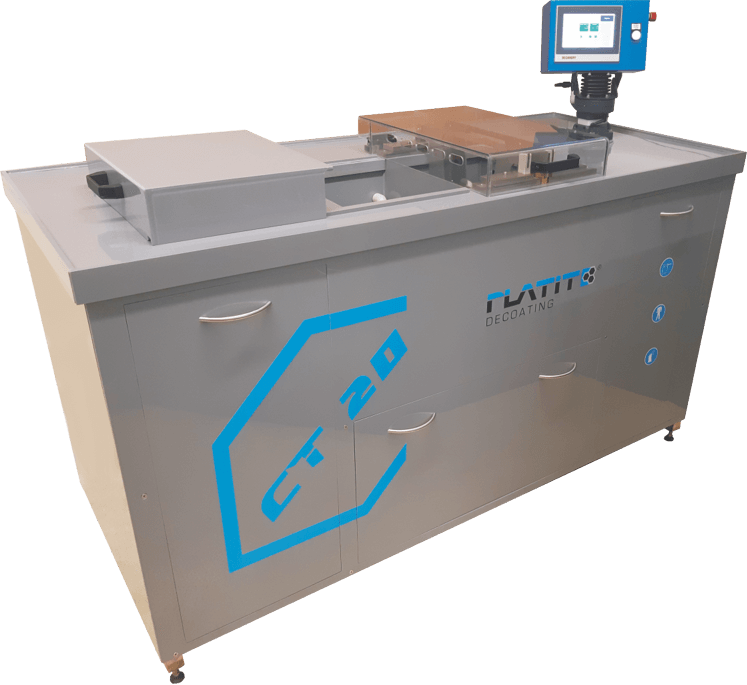

PLATIT CT20 – The ultra-fast decoating unit

The CT decoating units from PLATIT set new standards in decoating, especially for carbide tools. The problem of cobalt leaching is avoided by coating the substrate with a TiN adhesive layer, since the decoating process of the CT systems does not attack the TiN adhesive layer and thus protects the substrate.

With the CT20, the decoating cycle through to the TiN adhesion layer takes less than three minutes. The end of this process is automatically detected and terminated by the built-in electronics. The adhesive layer is not removed and consequently “overcoated” after regrinding and pre-treatment. This means that tools will achieve a service life comparable to that of a new tool.

The CT20 is PLATIT’s patented, environmentally friendly, wet-chemical carbide decoating unit.

- The world’s fastest decoating process: Decoating time is less than 3 minutes to the TiN adhesion layer and the decoating cycle stops automatically at the TiN adhesion layer

- A single recipe for a wide variety of nitride coatings with TiN adhesion layer, regardless of tool sizes

- Allows multiple coatings to be removed

- Special holders for shank tools, hobs, inserts, etc. prevent uncoated areas from being attacked

- Tool dimensions: max. ø200 x 250mm

- Use of chemicals that are available worldwide

- The process takes place at room temperature, so no heating or cooling is required

- The end of the process is automatically detected, which greatly simplifies the operator’s daily practice

Learn more about the decoating unit from the following article: "Productive Decoating of PVD Coatings"

PLATIT ST – The conventional decoating units

ST decoating units from PLATIT stand for high work safety and flexibility. Depending on the module, they strip Ti- or Cr-based layers from hard metal or high-speed steel:

- HM module to decoat Ti-based coatings from carbide

- CR module to decoat Cr-based coatings from carbide and high-speed steel

- HSS module to decoat Ti-based coatings from high-speed steel

- R Rinsing module

- P Protection module

For more information on the decoating process, see our Compendium on pages 90 to 95. Just click here or contact us directly.