Interesting facts about coating structures with PVD coatings

Coating units can produce a wide range of coatings. Depending on the application, the type of material is defined, as well as the coating structure. For example, tool coatings require a different coating structure than sputter coatings on watches or functional components.

- Monoblock

- Gradient

- Multilayer

- Nanolayer

- Nanocomposite

- TripleCoatings

- QuadCoatings

Monoblock structure

A monoblock (MB) coating consists of a continuous single-layer nitride coating. This single layer can be built up on an adhesive layer (e.g., TiN+AlTiN-MB).

If the adhesive layer and monoblock do not differ, the target material is not changed in the PVD coating process.

Gradient structure

The so-called gradient structure (G) is formed when the composition in the coating changes continuously. Such coatings consist of an adhesive layer and a core layer.

A typical example of a gradient structure is TiAlN/AlTiN-G.

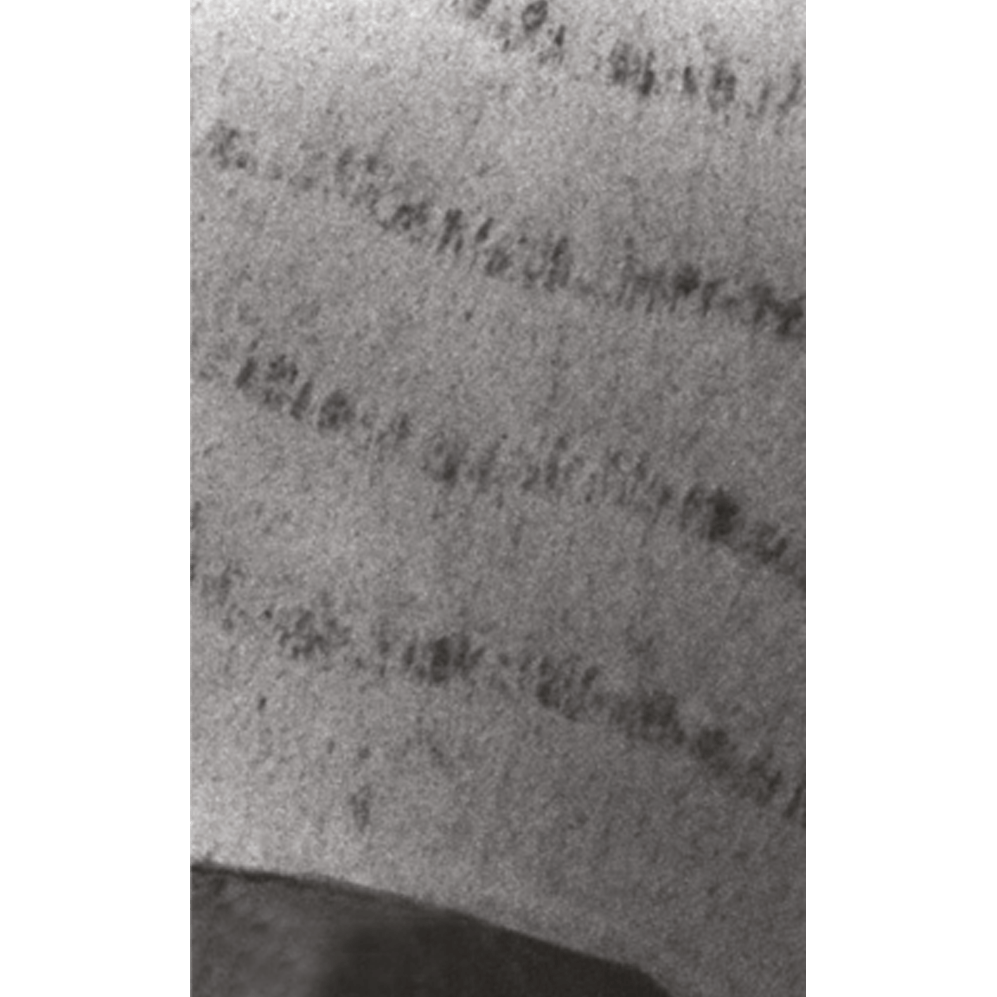

Multilayer structure

A multilayer (ML) coating structure also consists of an adhesive layer and a core layer. After the adhesive layer, however, several (multiple) layers are deposited in succession. Thanks to the multilayer, a “sandwich” structure is created, which can minimize cracking, for example. Coatings with this structure are tougher but less hard than a monoblock.

The thickness of a single layer in ML is typically 50-100nm, such as in AlCrN-ML.

Nanolayer structure

Nanolayer (NL) coating structures with a coating thickness of <20nm are even finer than multilayers. The coating hardness depends on the coating thickness period. To increase the hardness, a period of about 10nm should be set.

All PLATIT coatings with metallic targets exhibit the NL structure.

Nanocomposite structure

Nanocomposites (NC) consist of an adhesive layer and a core layer. The core layer is formed in 2 phases: Hard, nanocrystalline grains (e.g., TiN, TiAlN or AlCrN grains) are coated with an amorphous SiN matrix, preventing grain growth, and creating the nanocomposite structure. Column growth is avoided, and a fine crystalline, amorphous structure is formed.

One example of nanocomposite structure is nACo.

How the nanocomposite structure increases hardness can be illustrated with a simple comparison: On the beach, your foot usually sinks into the dry sand. On the other hand, if the sand is wet, your foot will not sink in as far because the space between the grains of sand is filled with water. The surface has a higher resistance and is therefore harder.

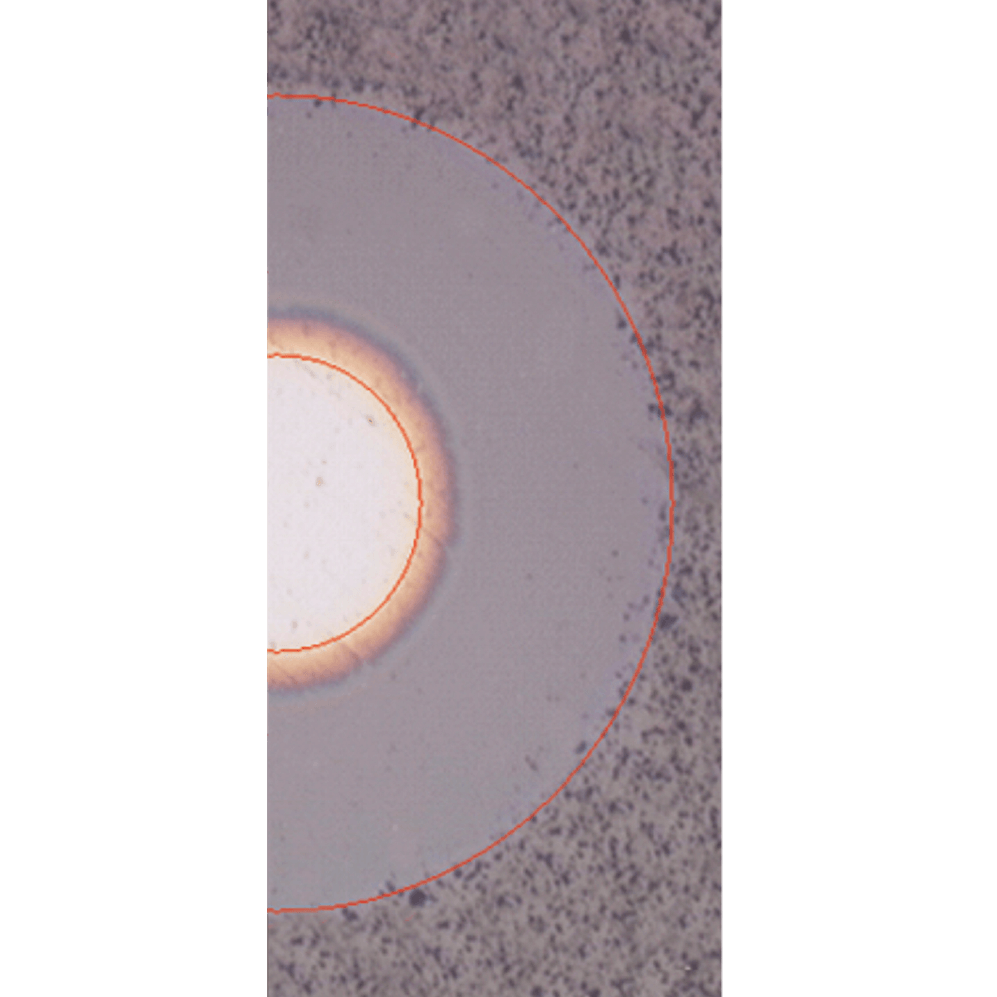

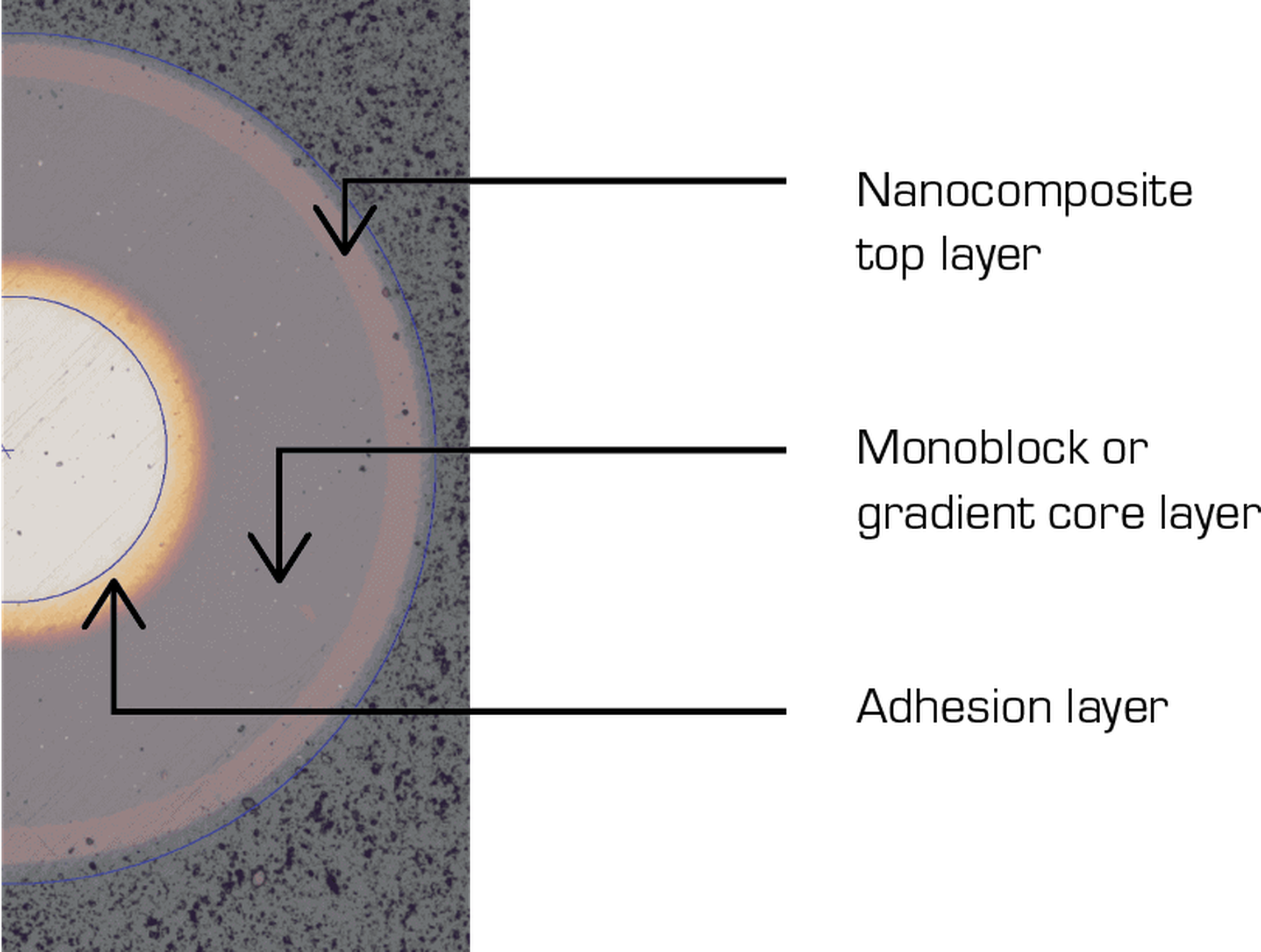

TripleCoatings

TripleCoatings from PLATIT consist of an adhesive layer, core layer (MB or G) and nanocomposite top layer.

A typical coating is nACo, which can be produced, for example, with the Pi411 PLUS coating unit.

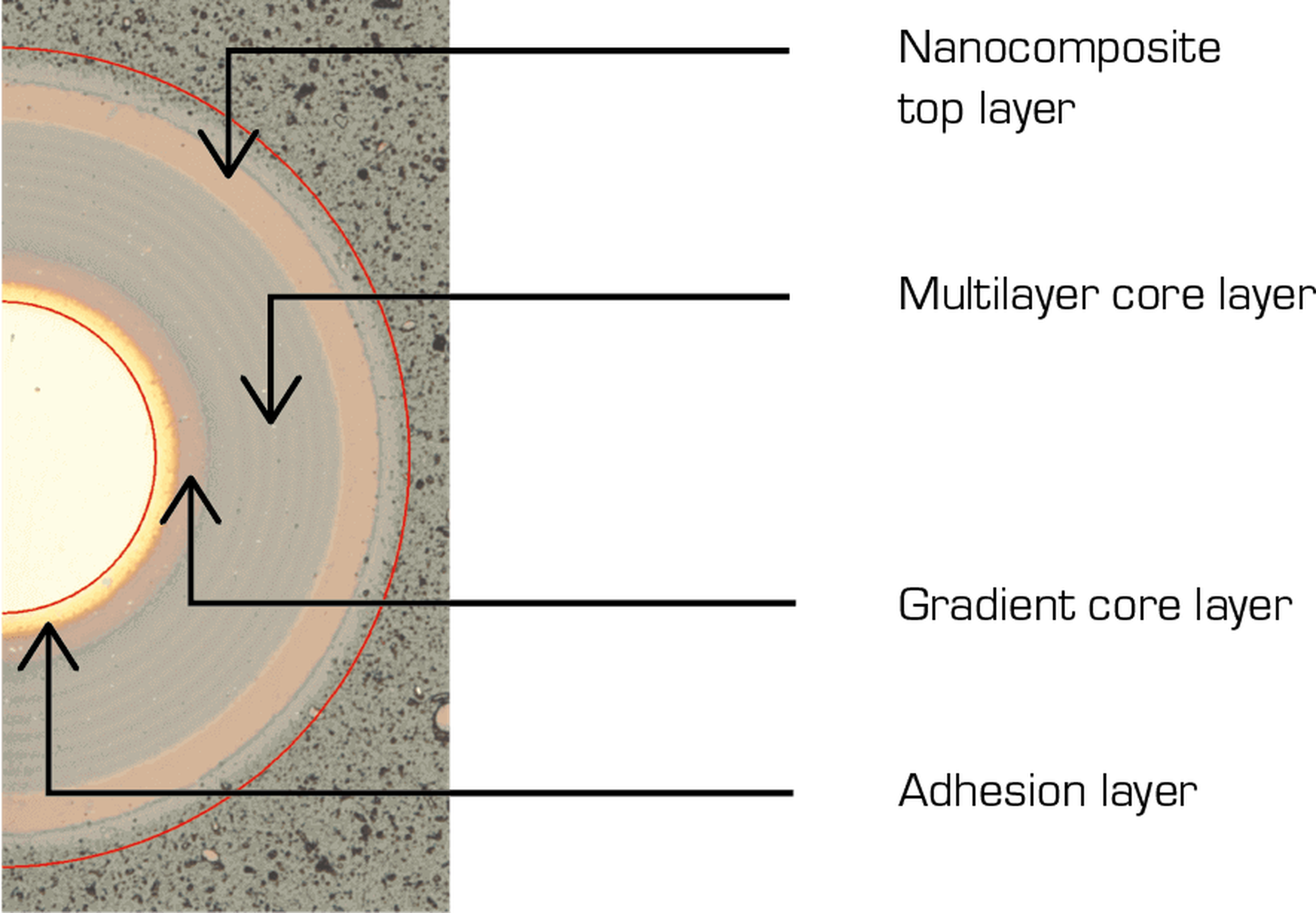

QuadCoatings

In addition to the triple structure, PLATIT QuadCoatings have a fourth block for special purposes. They consist of an adhesive layer, first gradient core layer, second multilayer core layer and a nanocomposite top layer.

A typical QuadCoating is TiXCo4.